©2024 FAN SEPARATOR GmbH

As the costs of high-quality bedding material have increased enormously in recent years, a growing number of innovative dairy operations are turning to organic bedding material produced on their own farms. This consists of the undigested fibrous material (food remains) extracted from manure. The BRU concept (Bedding Recovery Unit) developed by FAN separates, dries and hygienically prepares undigested fibres from the slurry. This can yield a tremendous reduction in operating costs while at the same time optimising milk production. Because it makes use of an ecological cycle, it eliminates the expense of purchasing bedding as well as the corresponding disposal costs. The organic material is continuously produced directly on the farm and is therefore always available.

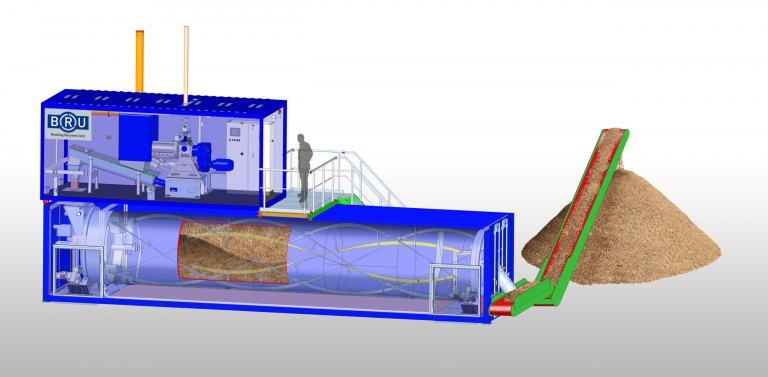

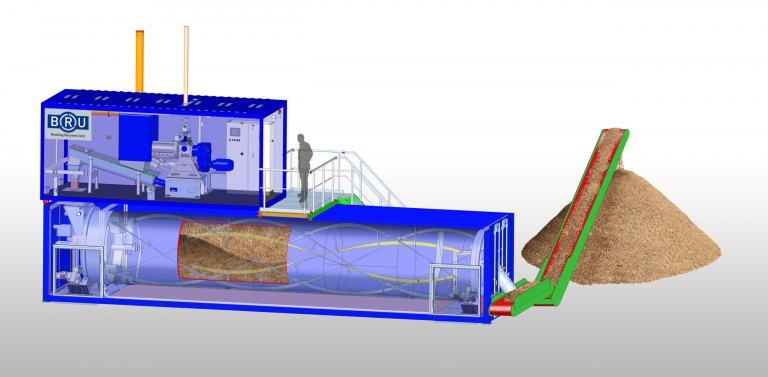

The first step in the process consists of separating the coarse solids and takes place in a specially designed press screw separator. The solids are primarily undigested residue from the feed, such as fibres from silage or hay. The separator segregates the liquid and solid parts, reducing the moisture content in the solid phase to a minimum. This solid is then further transported by a screw conveyor into a specially developed rotating drum made of stainless steel.

The second step in the process takes place in an insulated stainless steel drum. The solid is subjected to an intensive biological aerobic hygienisation process over many hours at temperatures of up to 65 degrees, during which the bacteria are killed or reduced to a minimum. This controlled and monitored process yields a homogeneous product and significantly counteracts the growth of mastitis pathogens, amongst others. Laboratory tests by various universities have confirmed that no detectable bacteria cells were present in the bedding material after this process.

BRU 400

Organic bedding production per day

BRU 1000

Organic bedding production per day

BRU 2000

Organic bedding production per day

The second step of the process happens in the FAN composting drum, which is installed in an insulated 40' container. The solids are fed into the drum via a patented flap system so that the drum can be filled to over 70% of its volume. In the drum, the material is continuously mixed and subjected to an intense aerobic process, during which air is sucked out of the drum to remove moisture from the system. For an optimal composting process, the air temperature is kept at around 65-70°C. A homogeneous product is produced by a stable, continuous process.

Thanks to the new discharge system the drum can be filled to 70% of its volume, this means a daily production of up to 46m3 of bedding material.

In order to ensure the fully automatic controlled operation, a special control unit has been developed, which guarantees a constant dry matter content of 36-38% at the separator outlet.

The whole unit as well as the single components can be controlled via the generously dimensioned touch screen panel. Data such as temperature and all setting parameters of the unit can be stored on memory cards over a longer period of time in order to ensure traceability. Furthermore, peripheral devices can also be controlled.

The German agricultural cooperative Agrargenossenschaft Reichenbach, who manages a dairy operation with 1,000 cows, has been usine the BRU 2000 since 2017. The farm ecompasses around 1,800 ha of agriculturally usable land. very day, 25 m3 of material is processed, which amounts to one third of the farm's slurry output. The agricultural cooperative, with its 54 employees, stores the separated bedding in a purpose-built bunker. Five to seven tons of material are produced and then distributed in the stalls every two days after mixing with lime. Previously, the company repeatedly had problems with the bedding used, which was contaminated with germs. Since the BRU was purchased, these have been a thing of the past.

After the BRU 1000 was put into operation on the farm in Ihász (Hungary) the milk output increased by a full 12%, i.e. from 9,200 kg to 11,000 kg! But people are also very satisfied with the FAN system in other ways: operating costs are lower and transport is reduced because there is no need to purchase bedding material (straw was previously used). The material is easy to handle, soft and loose and is well accepted by the cows. The animals are also clean. The BRU is regularly maintained and has functioned consistently reliably since it was put into operation in 2010. Every quarter a sample of the bedding material is sent to the laboratory and examined in detail. The result is as excellent today as it was 14 years ago.

Call us:

+499227938400

E-Mail us:

info@fan-separator.de

https://www.facebook.com/fanseparator