©2024 FAN SEPARATOR GmbH

The PSS series is a classic among FAN separators. It was the first series created, four decades ago now, and it served as the basis for all the others. Over the course of the years, the machine and its functions have been continually perfected and refined as the technology has matured. Numerous patents document the development of the press screw separator and serve as proof of FAN’s technology leadership. The applications are diverse: from agriculture to biogas production, from food processing to the paper industry. The press screw separator PSS covers a broad spectrum of uses.

The secret of the versatility of the Press Screw Separator PSS is that it can adjust to different dry matter contents. Thick liquids (20% dry matter content) as well as thin liquids (below 0,1 % dry matter content) can be treated optimally. The consistance of the gained solid can be varied with the help of a patented output regulator by the amount and position of counter weights. This enables dry matter contents in the range between 25 and 55 percent.

This way the required consistency of the final product for either further storage, use as fertilizer or the basis for compost can be reached. The liquid phase can easily be drained through a pipe or hose system. Compared to conventional separation systems the PSS is time and cost efficient.

Since 1986 FAN is dealing with separation technology and is proprietor of numerous patents. Currently more than 12.000 machines in different fields of applications are in use.

Separator principle ( Patent EP 0 367 037/ USA Patent Nr. 5, 009, 795)

Oscillator system ( Patent EP 0 443 385/ USA Patent Nr. 5, 118, 427):

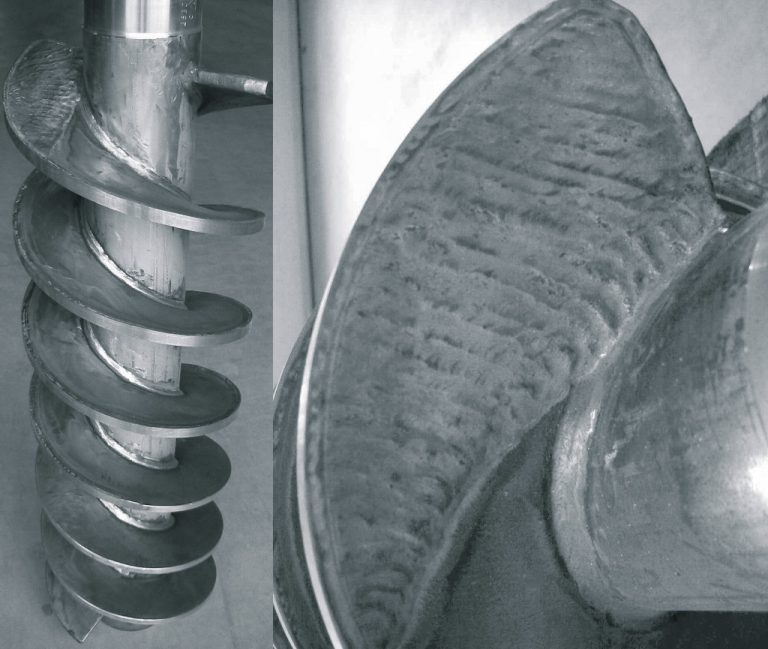

The high quality of the materials used keep the maintanance costs low. The auger and screen baskets as well as the guide rails are made of high quality stainless steel. The coils of the auger are thick walled stainless steel coils which are protected against wearing by an armour coating. Different designs of the auger and the coating enable that the machine adapts to different mediums. Furthermore, teflon coatings for special applications are available. For the food and paper industry housings made of stainless steel are available

The inlet housing is provided with a gear tooth system in order to shred long fibres. This way the throughput of such mediums can be increased. A housing protection ring between screen and inlet housing functions as a wearpart and prevents damage of the inlet housing.

Different feeding varieties like feeding via a hopper of mediums which cannot be pumpend or feeding via a pipe system is possible. The patented oscillator unit produces additional vibrations which are led directly into the medium in order to increase the throughput. This is an advantage with viscous mediums.

When separating greasy mediums a special flushing device helps cleaning the screens. This can be done with different liquids even by adding chemicals, the flushing device is interval operated. Furthermore, a jamming of the screens can be prevented when the seperator is not in use.

Separation of solid and liquid manure of pig, cattle and poultry manure.

In addition to other factors, sufficient resting periods are also crucial for the milk yield of cows. The animals prefer soft, dry and clean lying areas. Therefore the choice of the right bedding material plays a key role: organic bedding produced in-house with FAN machines fulfils all the essential criteria to ensure that your animals feel comfortable:

Resource conservation, reintroduction of reusable substances into economic circulation and inexpensive disposal that is easy on the environment are all key topics for municipal services providers. In this setting as well, FAN separators do valuable work, for example:

or